Step-by-step instructions for connecting the air pipe to the foot press bowl压脚碗气管连接步骤

Time: 2025-08-30 09:54:56.154

Step-by-step instructions for connecting the air pipe to the foot press bowl

Technical Guidance: Mr. Lin Senwen

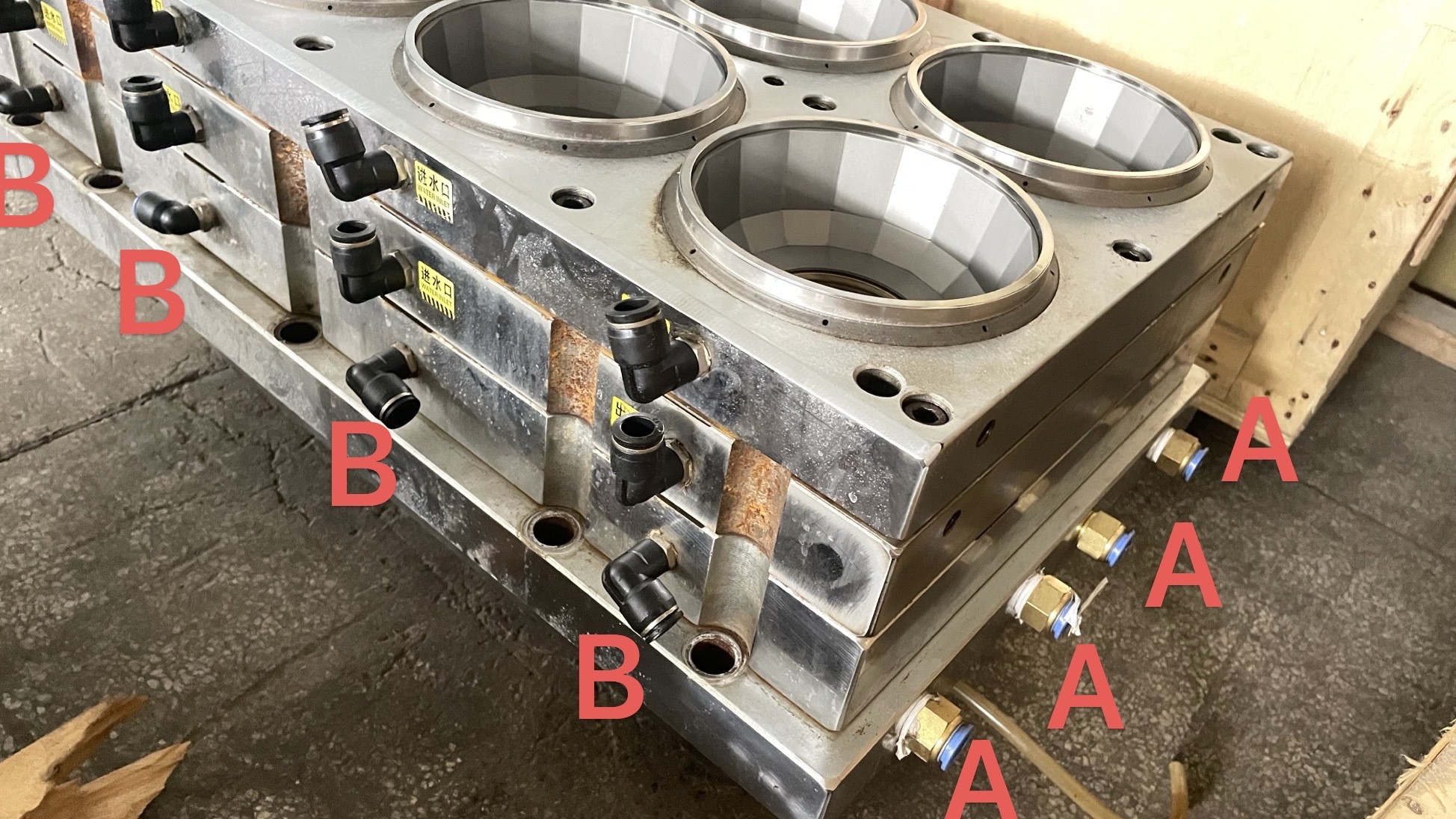

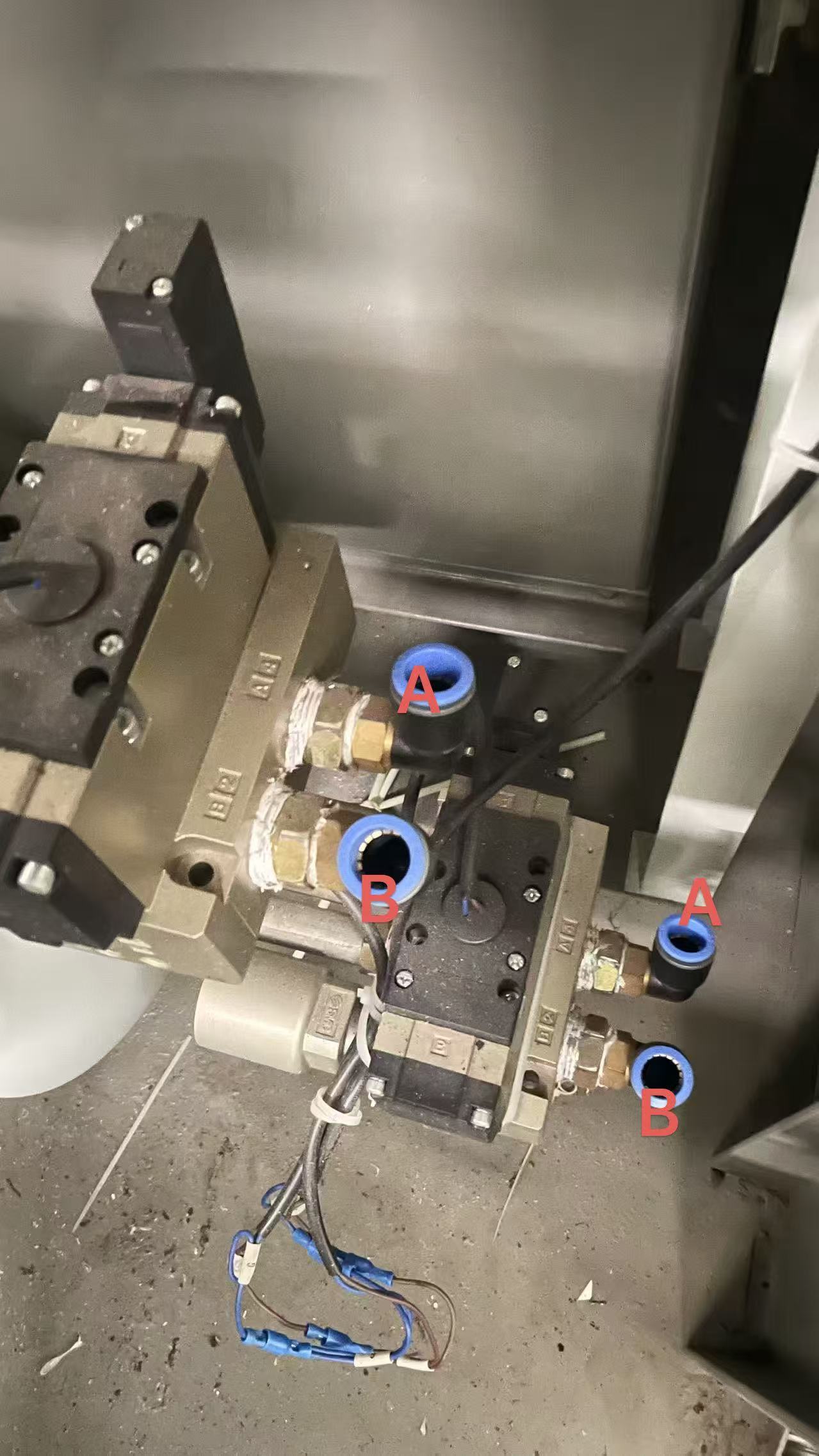

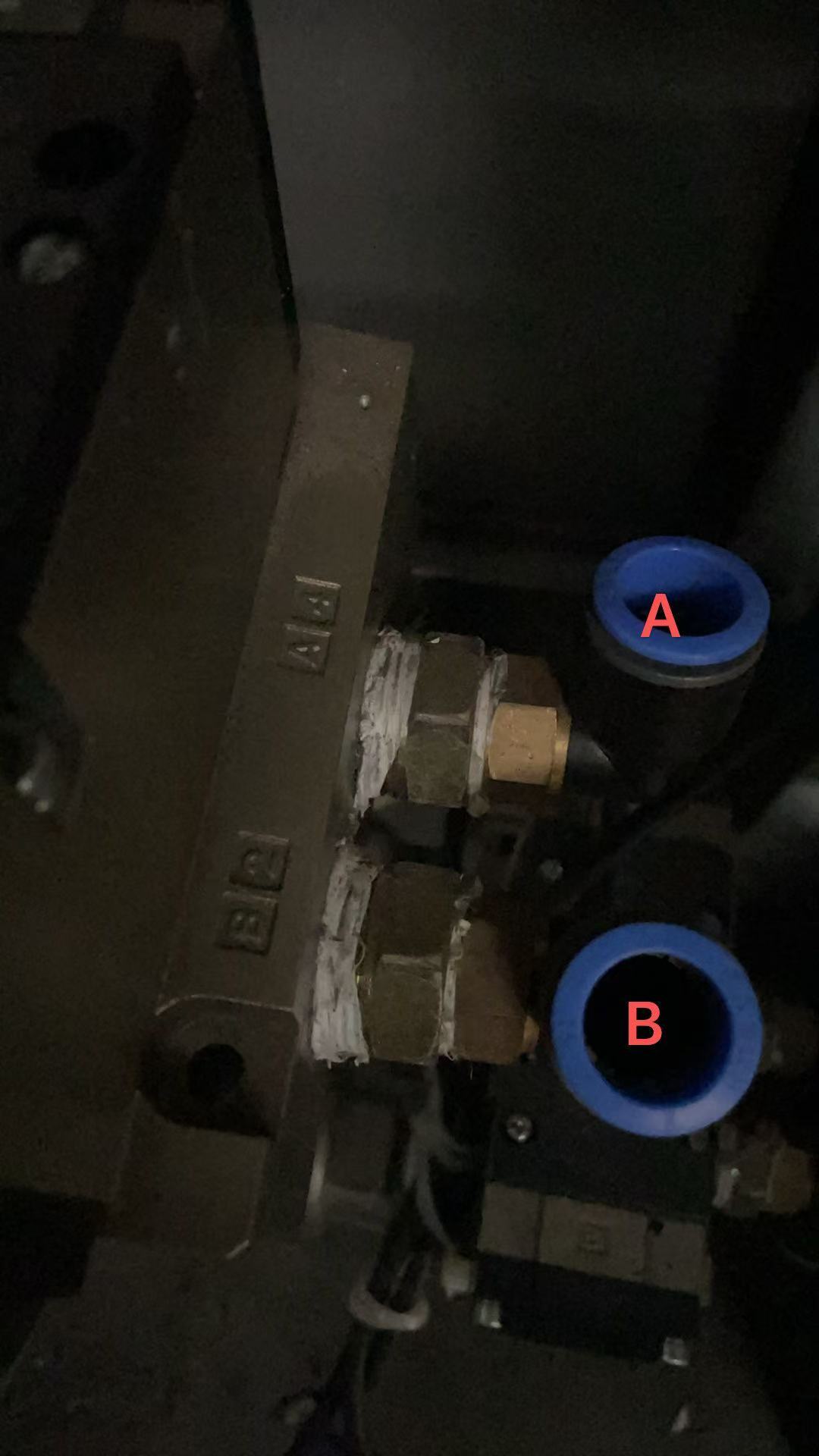

Connect A to A, B to B. If the holes are insufficient, use a three-way connector to split them.

A接A B接B 孔位不够用三通化开

Important note: Before performing any operation, please ensure that the equipment is powered off, disconnected from the air supply, and in a safe state.

Step 1: Identify the interface of the solenoid valve

Locate your two-position five-way solenoid valve. It usually has 5 air ports. There are usually letter markings beside the ports:

P: Pressure air inlet. Connect the air source, and the compressed air enters the solenoid valve from here.

A and B: Working output ports. These two ports are connected to the two ports of the cylinder (A port and B port) to control the extension and retraction of the cylinder.

R and S: Exhaust ports. Usually equipped with a muffler (a small tail-shaped component), used to direct the air discharged from the cylinder to the atmosphere. Some valves have separate exhaust ports, while others share them.

Step 2: Connect the air source to the solenoid valve

1. Connect the main air source pipe (usually processed through a three-piece set) to the P port of the solenoid valve with a suitable air pipe fitting.

2. Ensure that the air pipe is fully inserted and securely fastened with a clamp to prevent disconnection under high pressure during operation.

Step 3: Connect the solenoid valve to the mold cylinder

This is the most crucial step.

1. Locate the foot press cylinder on the mold. It will have two air ports. Some molds with more cavities may have four air ports (assuming it is a standard double-acting cylinder).

2. Use two long enough air pipes to connect the A port of the solenoid valve to one of the air ports of the cylinder.

3. Connect the B port of the solenoid valve to the other air port of the cylinder.

Note:

What if the A port and B port are connected in reverse? This will cause the extension and retraction actions of the "foot press" to be opposite to the electrical control signal. That is, when it should be pressed down, it will be lifted, and when it should be lifted, it will be pressed down. This is very dangerous and may cause mold damage or personal injury!

How to test if it is correct? After completing all connections, when the mold is not open and not in production, manually trigger the solenoid valve (usually there is a manual test button on the valve) and observe the action of the foot press. If the action direction is reversed, simply swap the two air pipes connected to the A port and B port.

Step 4: Handle the exhaust ports

Ensure that the exhaust ports R and S of the solenoid valve are unobstructed. If a muffler is installed, check if it is intact. Unobstructed exhaust is crucial for maintaining stable cylinder speed and the normal operation of the valve.

压脚碗气管连接步骤

重要提示:在进行任何操作前,请确保设备断电、断气,并处于安全状态

第1步:识别电磁阀的接口

找到您的两位五通电磁阀。它通常有 5个 气路口接口旁边通常有字母标识:

P: 压力进气口。连接气源,压缩空气从这里进入电磁阀。

A和 B: 工作输出口。这两个口连接至气缸的两个接口(A口和B口),用于控制气缸的伸出和缩回。

R和 S: 排气口。通常装有消声器(小尾巴状的部件),用于将气缸排出的空气导出到大气中。有些阀的排气口是独立的,有些是共用的。

第2步:连接气源到电磁阀

1. 将主气源管道(通常经过三联件处理后)通过合适的气管接头连接到电磁阀的 P 口。

2. 确保气管插到底,并用卡箍固定好,防止工作时高压脱开。

第3步:连接电磁阀到模具气缸

这是最关键的一步。

1. 找到模具上的压脚气缸,它会有两个气口,有的模具腔数比较多,有可能有4个气口(假设是标准双作用气缸)。

2. 用两根足够长的气管,将电磁阀的 A口连接到气缸的 一个气口。

3. 将电磁阀的 B口连接到气缸的另一个气口。

注意:

A口和B口接反了会怎样?这会导致“压脚”的伸出和缩回动作与电控信号相反。即本来该压下的时候它抬起,该抬起的时候它压下。这非常危险,可能导致模具损坏或人身伤害!

如何测试是否正确?完成所有连接后,在模具不开模、不生产的情况下,手动触发电磁阀(通常阀上有一个手动测试按钮),观察压脚动作。如果动作方向反了,只需将 A口和B口的两根气管对调即可

第4步:处理排气口

确保电磁阀的排气口 R和 S通畅,没有被堵塞。如果装有消声器,检查其是否完好。通畅的排气是保证气缸速度稳定和阀正常工作的关键。

Related News

Thermoforming Machine Manufacturer

A thermoforming machine is a key piece of equipment in the manufacturing industry. It heats plastic sheets until they're pliable, then shapes them into desired forms using molds. This process is efficient and cost - effective.

PE Extruder Machine Manufacturers: Insights into the Evolving Industry Landscape

PE Extruder Machine Manufacturers: Insights into the Evolving Industry Landscape Table of Contents 1. Introduction to PE Extruder Machines 2. Understanding PE Extruders: Definition and Functionality 3. Key Manufacturers in the PE Extruder Machine Market 4. Global Market Analysis: Trends and Growth 5. Technological Advancements Shaping the Industry 6. Applications of PE Extruders in Va

Exploring the Best Bioplastic Manufacturing Machines for Sustainable Production

In the realm of manufacturing and processing machinery, particularly in the plastic processing sector, the emergence of bioplastics presents both opportunities and challenges. To effectively engage in this burgeoning market, identifying the best bioplastic manufacturing machines is crucial. These machines are designed to produce environmentally friendly plastic alternatives that can significantly

Choosing the Right Pet Sheet Extruder Machine Supplier: Key Considerations for Professionals

When it comes to sourcing a pet sheet extruder machine supplier, professionals in the manufacturing and plastic processing sectors should take into account several vital factors to ensure they make an informed decision. The pet sheet extruder machine is a critical piece of equipment used for producing polyethylene terephthalate (PET) sheets, which have applications in various industries, including

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok