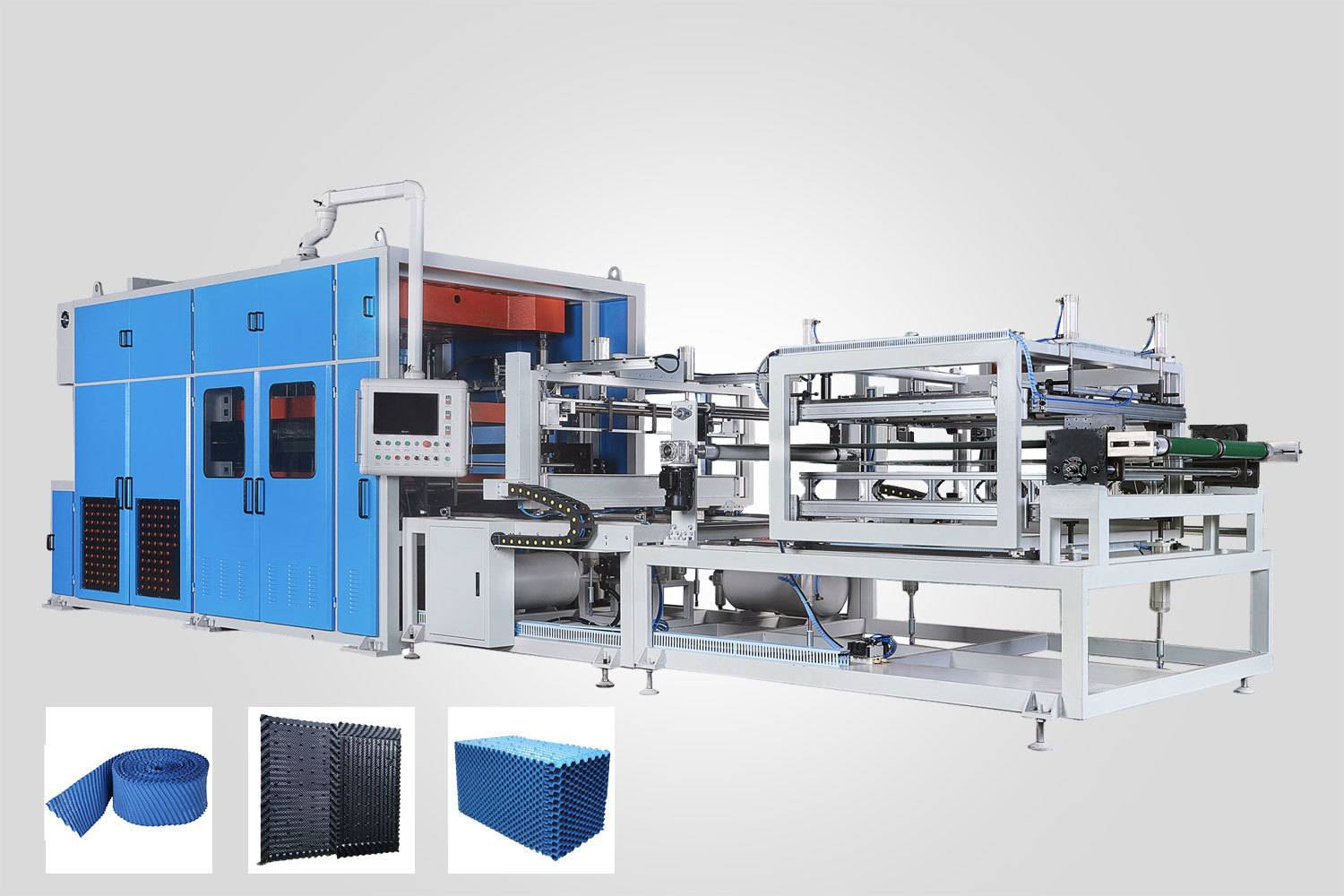

Unit features:

1. The forming group is connected with the cross-cutting knife frame, which is suitable for thermoforming of various types of sheets, especially for condenser water-spraying plastic sheets.

2. The machine and the matching mold are designed with repeated sections. No joint lines are produced at the joint of each version of the product.

3. The working mold table adapts to the mold area and the area of the product after shearing is 1650*1650.

Sheet production process:

→ Plastic sheet loading → Preheating → Hot pressing molding → Demolding → Cross-cutting → Longitudinal cutting → Conveying.

Engineered for high-output manufacturing and exceptional versatility, our Thermoforming Machine delivers unmatched performance for producing consistent, high-quality plastic products. Designed with innovative features like a integrated forming group and cross-cutting knife frame, it seamlessly handles various materials—including condenser water-spraying plastic sheets—with precision and speed.

Key advantages of our Thermoforming Machine include:

- Seamless Production: The unique mold design with repeated sections eliminates joint lines, ensuring flawless product surfaces and structural integrity.

- Large Format Capacity: A generous working mold area (16501650) accommodates oversized sheets, maximizing productivity for industrial-scale projects.

- Automated Workflow: From sheet loading and preheating to hot pressing, demolding, cross-cutting, longitudinal cutting, and conveying, the process is streamlined for efficiency and minimal manual intervention.

- Durability & Adaptability: Robust construction guarantees long-term reliability, while flexibility in mold configurations supports diverse product designs.

Ideal for packaging, automotive components, and specialized parts like condenser sheets, this Thermoforming Machine reduces operational costs, enhances output quality, and boosts ROI. Customizable options are available to meet specific production needs.

Partner with us for cutting-edge technology, comprehensive technical support, and global service. Elevate your manufacturing capabilities with our trusted Thermoforming Machine solutions.

Contact us today to discuss your requirements and request a personalized demonstration!

| Machine Type | LS125-125 |

| Processing Materials | PP、PVC、PLA |

| Maximum Sheet Width | 1330mm |

| Sheet Thickness | 0.2~1.5mm |

| Fastest Forming Times | 6 times/min |

| Maximum Forming Area | 1250x1250mm |

| Maximum Forming Depth | 110mm |

| Total Power of The Whole Machine | ≈ 135Kw |

| Machine Dimensions | 13.5*2.6*2.7M |

| Power Source Used | 380V Three-phase four-wire (customizable) |

| Machine Weight | ≈ 8T |

| Water Source | Cooling water source or tap water |

| Air Source | 0.8MPa |

MADE IN CHINA

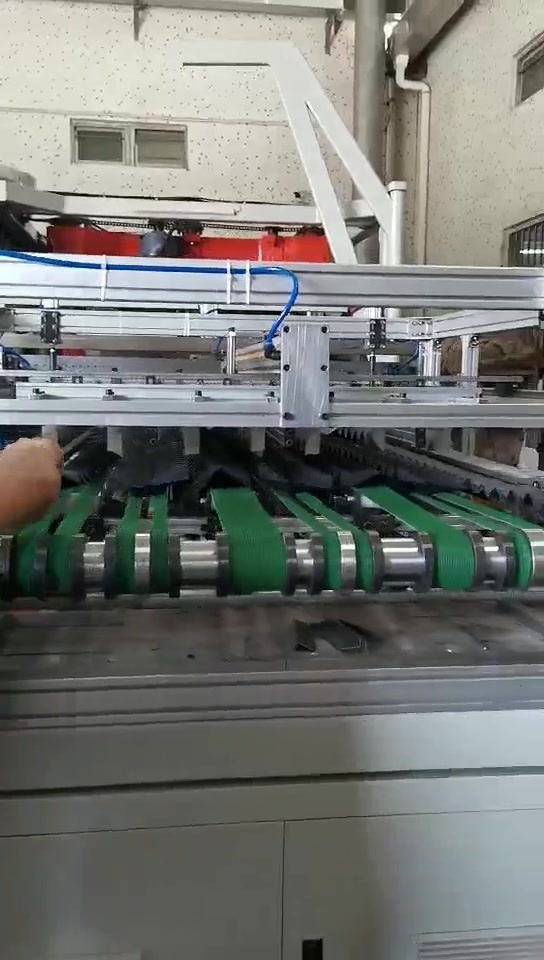

Related Video

Pvc Cooling Tower Water Filling Forming Machine

Pvc Cooling Tower Water Filling Forming Machine

Pvc Cooling Tower Water Filling Forming Machine

Pvc Cooling Tower Water Filling Forming Machine

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok