Functional features:

1. Mechanical, pneumatic, electrical integration. Each action program is controlled by PLC. Touch screen operation, simple and convenient.

2. Positive and negative pressure cooperate to form.

3. Upper and lower mold forming methods.

4. Servo feed, stepless length adjustment, high speed accurate and stable.

5. The upper and lower electric furnace are heated in four stages.

6. The electric furnace temperature control system adopts the whole computer intelligent automatic compensation control, and the partition control adopts the human-machine interface digital input. It has the advantages of high fine-tuning precision, uniform temperature, fast temperature rise (from 0-400 degrees only 3 minutes), stability (not affected by external voltage, temperature fluctuation does not exceed 1 degree), low energy consumption (energy saving about 15%), and long service life of the furnace plate.

7. Forming, cutting unit mold opening, mold closing servo motor control, product automatic counting output.

8. The product is stacked downward or taken out by supporting manipulator.

9. With product information and parameter file memory function.

10. Feed chain track width can be synchronized automatic or discrete electric adjustment.

11. Automatic removal device of electric furnace.

12. Mechanical feeding coil device, reduce the labor intensity of workers.

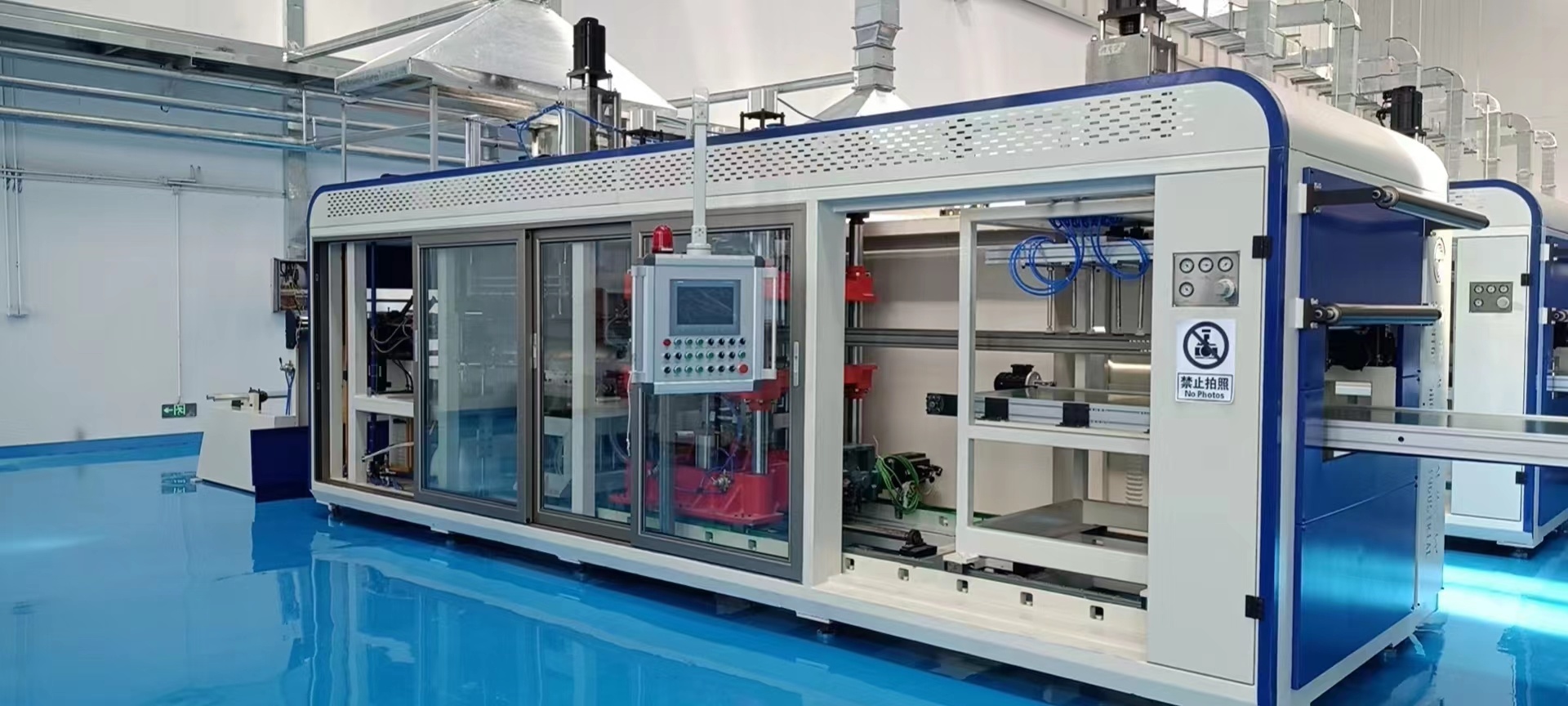

The multi-station thermoforming machine is a cutting-edge solution for high-volume plastic forming, designed to deliver unmatched productivity and consistency. Ideal for packaging, automotive, and consumer goods industries, this advanced machine streamlines production with multiple forming stations working seamlessly in one cycle.

Key features of the multi-station thermoforming machine include:

- High-Speed Production – Multiple stations enable simultaneous heating, forming, and trimming, drastically reducing cycle times.

- Superior Precision – Advanced PLC controls ensure accurate forming and consistent product quality.

- Material Efficiency – Optimized heating and forming processes minimize waste, lowering operational costs.

- Flexible Tooling – Compatible with various molds, allowing quick changeovers for different product designs.

Built for durability, the multi-station thermoforming machine incorporates robust components and energy-efficient systems, ensuring long-term reliability. Whether producing food containers, medical trays, or automotive parts, this machine guarantees high output with exceptional finish quality.

Upgrade your production line with the multi-station thermoforming machine – the ultimate choice for speed, precision, and cost-effective plastic forming. Experience seamless automation and superior performance for your thermoforming needs!

| Machine Type | FGW7292-III |

| Forming Area | 720× 920mm |

| Max. Forming Height | ≤150mm |

| Max. Forming Width | ≤680 |

| Sheet Thickness | 0.12-1.8mm |

| Suited Material | PP,PS,PET,PVC... |

| Speed | ≤15time/min |

| Gas Consumption | 2-3m³/min |

| Air Pressure | 0.6-0.8Mpa |

| Water Consumption | 1-2.5m³/h Circulating water |

| Machine Size | 12m×2.5m×3.5m |

| Machine Weight | 13T |

| Power Consumption | ≈72kw/h |

| Total power | ≈136KW |

MADE IN CHINA

Related Video

Negative pressure multi-station thermoforming machine

Negative pressure multi-station thermoforming machine

Negative pressure multi-station thermoforming machine

Negative pressure multi-station thermoforming machine

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok