Product Introduction

It is suitable to from PP, PS, HIPS, PVC, PET plastic sheets, which can be widely used to produce all kinds of plastic boxes, containers and other plastic wares, such as ice-cream, milk cups chocolate package boxes, candy boxes and fast-foo

Main features

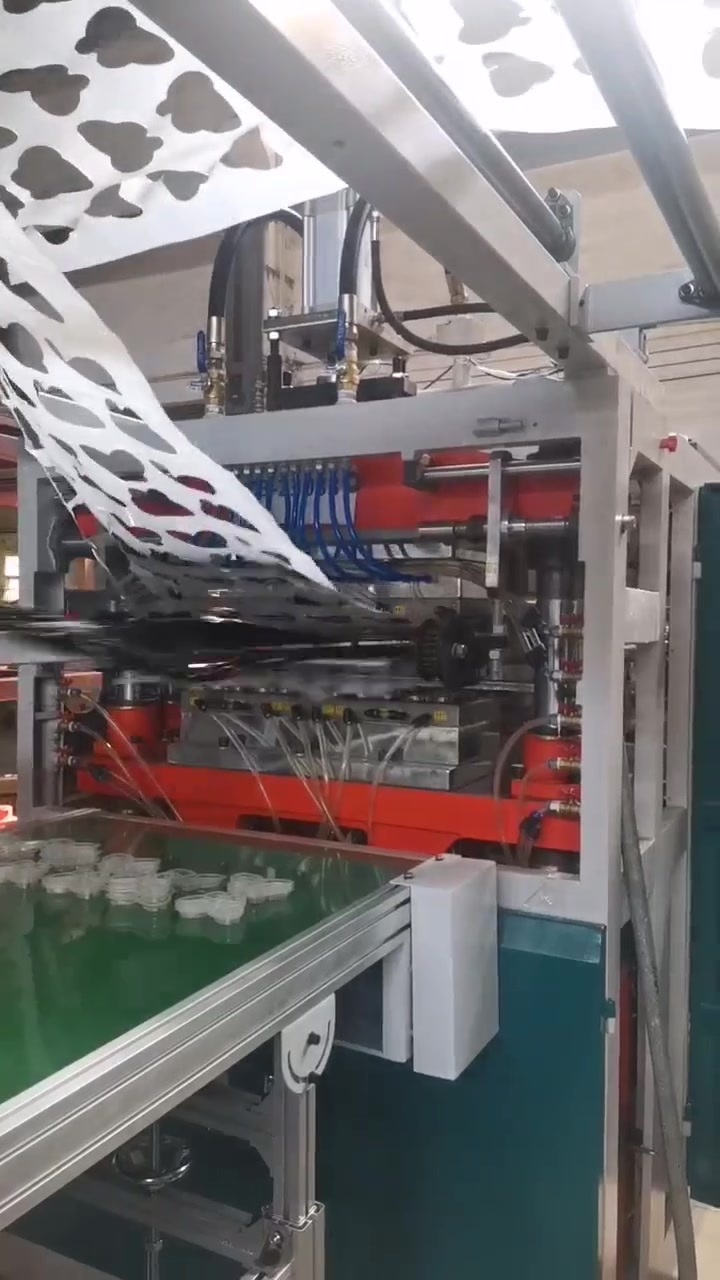

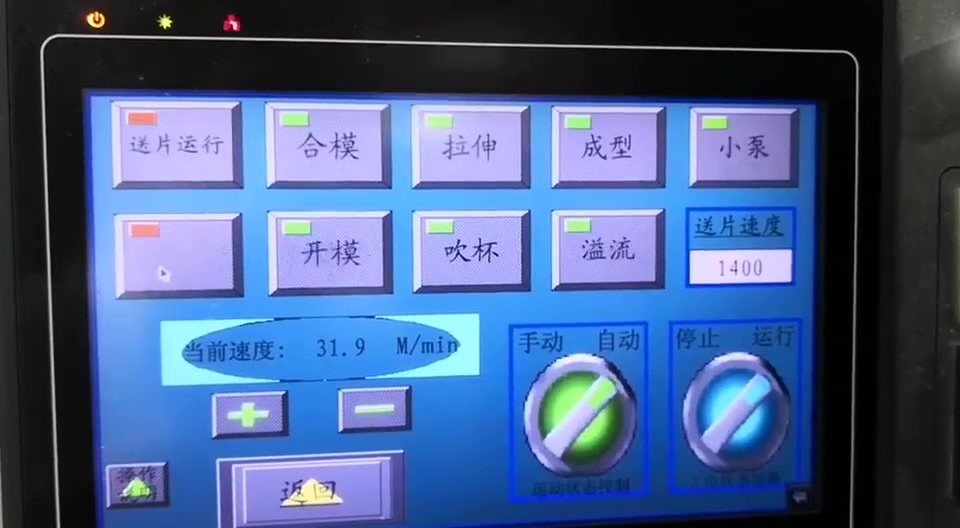

The machine is a combination of mechanical, electrical and pneumatic omponents, and the whole system was controlled by micro PLC. The machine has man-machine interface operation, sending sheet by chian, cutting by mould knives, Combines the preheating, material feeding, heating, drawing, forming, cutting and stacking into one process.

The Plastic Cup Making Machine represents a state-of-the-art solution for the high-volume manufacturing of a diverse range of disposable and semi-durable plastic containers. This fully automated system is engineered to transform polypropylene (PP), polystyrene (PS), high-impact polystyrene (HIPS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET) plastic sheets into finished products with exceptional efficiency and precision. The operational principle of this Plastic Cup Making Machine integrates multiple stages—including preheating, material feeding, high-temperature heating, vacuum drawing, precision forming, and automatic cutting—into one seamless, continuous process. This integrated workflow ensures maximum productivity and consistent output quality for items such as ice cream cups, dairy containers, chocolate packaging, candy boxes, and fast-food clamshells.

Constructed as a sophisticated combination of robust mechanical, reliable pneumatic, and advanced electrical components, this machine is controlled by a micro-programmable logic controller (PLC) for unparalleled operational consistency and ease of use. The inclusion of an intuitive human-machine interface (HMI) allows for straightforward parameter setting, real-time monitoring, and diagnostic control, minimizing operator intervention and technical expertise requirements. The material feeding system utilizes a stable chain-driven mechanism to ensure precise sheet alignment and consistent movement through each thermal and forming zone, while the cutting unit employs durable mould knives for clean, sharp, and burr-free edges on every finished product.

Designed for industrial endurance and low maintenance, this Plastic Cup Making Machine is the cornerstone of modern packaging production lines. Its ability to handle various polymer materials and quickly adapt to different product specifications through simple mould and parameter changes makes it an incredibly versatile and cost-effective investment. By automating the entire process from raw sheet to stacked finished goods, this machine significantly enhances production capacity, optimizes labor costs, and guarantees the high-quality output essential for competitive markets. The reliability and advanced automation of this Plastic Cup Making Machine make it an indispensable asset for any business focused on producing superior plastic packaging.

| Machine Type | HAI-7036-180 | HAI-7036-220 | HAI-7036-250 | HAI-7036-300 |

| Mold Table Size | 700mmx360mm | 700mmx360mm | 700mmx360mm | 700mmx360mm |

| Maximum Molding Area | 700mmx290mm | 700mmx290mm | 700mmx290mm | 700mmx290mm |

| Machine Stroke | 180mm | 220mm | 250mm | 300mm |

| Maximum Product Height | 125mm | 180mm | 200mm | 250mm |

| Sheet Thickness Range | 0.5mm~3mm | 0.5mm~3mm | 0.5mm~3mm | 0.5mm~3mm |

| Sheet Width | ≤720mm | ≤720mm | ≤720mm | ≤720mm |

| Gas Consumption | 0.9m³-1.5m³/min | 0.9m³-1.5m³/min | 0.9m³-1.5m³/min | 0.9m³-1.5m³/min |

| Air Pressure | ≤0.8Mpa | ≤0.8Mpa | ≤0.8Mpa | ≤0.8Mpa |

| Water Consumption | ≤1.5m³/h | ≤1.5m³/h | ≤1.5m³/h | ≤1.5m³/h |

| Heating Power | 116.4KW | 116.4KW | 116.4KW | 116.4KW |

| Frequency Feed Power | 3.7KW | 3.7KW | 3.7KW | 3.7KW |

| Hydraulic Clamping Power | 11.0KW | 11.0KW | 11.0KW | 11.0KW |

| Stretching cylinder | 125mm | 125mm | 160mm | 160mm |

| Production Speed | ≤35Mold/ MIN | ≤35Mold/ MIN | ≤35Mold/ MIN | ≤35Mold/ MIN |

| Machine Size | 7.2mx1.9mx2.6m | 7.2mx1.9mx2.7m | 7.5mx1.9mx2.8m | 7.5mx1.9mx3.2m |

| Machine Weight | ||||

| Total Power | 130.0KW | 130.0KW | 134.0KW | 134.0KW |

| Adjusting mold method | Standard model: manual mold adjustment Advanced model: electric modulator |

|||

MADE IN CHINA

Related Video

Hydraulic Cup Making Machine

Hydraulic Cup Making Machine

Hydraulic Cup Making Machine

Hydraulic Cup Making Machine

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok