A, Main configuration:

1. Machine frame uses international steel and international proximate matter

2. Move controlled by 0.75kw servo driver (Mitsubishi/dapan) controlling seryo motor (Mitsubishi), positiol accurately.

3. Stacker action uses lkw servo driver (Mitsubishi/Japan) controlling servo motor (Mitsubishi) . counting and stacking accurate

4. Magnetic valve uses SMC, instant reactior

5. Material of up and down moving guide way is from HIWIN.

6. Moving controlled by servo motor with synchronous belt, greatly satisfied the speed and accuracy of grabbing and stacking

7. Sucking cup part uses SMC, material is silica gel, better ensure the safety of mould

8. Conveyor uses 0.55kw motor, with counting.

B. Main configuration of electrical part

1. Moving by servo controller: 0.75kw servo controller (Mit-subishi/Japan)

controlling 0.75kw servo motor

2.Stack controlled by servo controller: lkw servo control-ler( Mitsubishi/Japan)

controlling lkw servo motor

3.Human-computer interface: move control

4.Connect with cup making machine signal cables: commu-

nication line

5. Suck product: SMC vacuum generator

6. Feeding: controlled by 105kw frequency converter

7. Signal、 proximity switch: 0mron

8. Switch、terminal blocks: Schneider/France

| Grab and stacked number: | cup making machine forming speed |

| Air pressure: | 0.8Mpa |

| Voltage: | 220V2P |

| Advantage: | automatically grab、stack and coun |

| Grab and feeding: | counting and feeding to the convey belt |

| Main machine size: | L 1300*W600*H2000mm 350KG |

| conveyor size: | :L3000*W800*H1100/150070KG |

MADE IN CHINA

Related Video

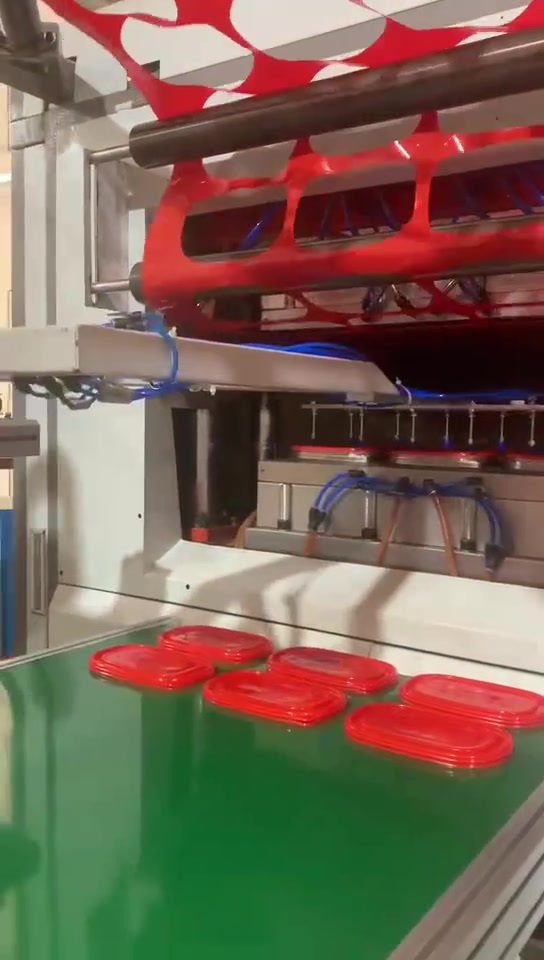

Manipulator

Manipulator

manipulator

manipulator

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok