Main features:

1, used in the production of polyethylene terephthalate (PET), biodegradable plastic polylactic acid, starch based degradation materials and other sheets.

2, using large length-diameter ratio screw, plasticizing effect is better, pressure is more stable.

3, equipped with crystallization drying system, pre-crystallization drying, reduce plasticizing time, improve product quality and production speed.

4, the die is made of alloy material, reasonable structure, wear resistance, uniform heat, easy adjustment.

5, melt metering pump quantitative pressure output, and equipment pressure and speed closed-loop automatic control.

6, three roller independent adjustment is consistent, synchronous adjustment operation is convenient.

7, equipped with center flip double station winding, occupying less land, easy to change coil, winding flat, reduce waste.

8, using PLC control, to achieve parameter setting, data calculation and feedback, alarm and other functions of automatic control.

Sheet Extruder is an advanced manufacturing machine designed to produce high-quality plastic sheets with uniform thickness and superior surface finish. Ideal for packaging, automotive, and construction industries, this robust equipment ensures efficient, continuous production of PP, PET, HDPE, and other thermoplastic sheets with customizable dimensions.

Key Features & Benefits:

✔ High Output Efficiency – Advanced screw design ensures smooth melting and consistent sheet extrusion for maximum productivity.

✔ Precision Thickness Control – Automatic gauge adjustment maintains ±0.02mm tolerance for uniform sheet quality.

✔ Energy-Saving Design – Optimized heating and cooling systems reduce power consumption while maintaining performance.

✔ Multi-Layer Capability – Co-extrusion options for laminated sheets with enhanced barrier properties.

✔ User-Friendly Operation – PLC-controlled system with touchscreen interface for easy monitoring and adjustment.

Applications:

- Packaging – Food containers, blister packs, and disposable trays.

- Automotive – Interior linings, dashboards, and protective panels.

- Building & Construction – Corrugated sheets, insulation boards, and decorative laminates.

- Consumer Goods – Signage, stationery, and display materials.

Why Choose Our Sheet Extruder?

Built for durability and precision, our Sheet Extruder guarantees high-speed production, low waste, and exceptional sheet quality—making it the ideal solution for modern plastic sheet manufacturing.

| Machine Type | XSI-75-950 | XSI-85-1000 | XSI-95-1000 |

| Screw Diameter | 75 | 85 | 95 |

| Length-Diameter Ratio | 44:1 | 44:1 | 44:1 |

| Main Motor Power | 165kW | 200KW | 200KW |

| Screw Heating Power | 50kw | 62Kw | 74kw |

| Three-roll Specification | 450x1000 | 520x1000 | 600X1000 |

| Three-roll Drive Power | 4KW*3 | 4KW*3 | 4KW*3 |

| Winding Mode | Center turning double station winder | Center turning double station winder | Center turning double station winder |

| Output | ≤400Kg/h | ≤600Kg/h | ≤800Kg/h |

| Machine Size | 16X2.5X3.2M | 18X2.5X3.2M | 20X2.5X3.2M |

| Machine Weight | ≈14T | ≈16T | ≈18T |

| Metering Pump | 176CC | 200CC | 200CC |

MADE IN CHINA

Related Video

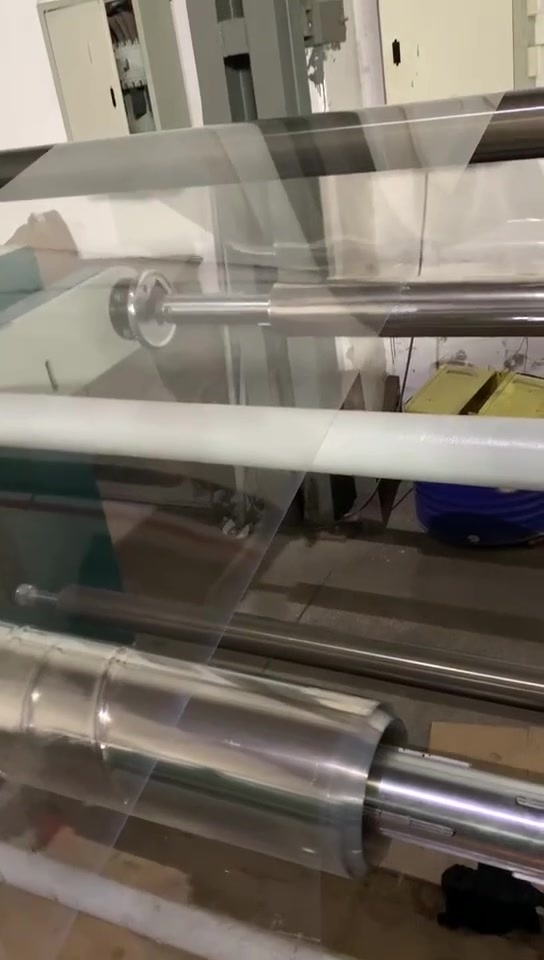

PET Sheet extruder

PET Sheet extruder

PLA sheet extruder

PLA sheet extruder

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok