Shantou Longsheng Industry Co., Ltd.

LS105/120/90-1000 Three-layer co-extrusion Sheet Machine (high configuration)

Main features:

1, used in the production of polypropylene (PP), polyethylene (PE), polystyrene (PS) and other plastic sheets.

2, using large length-diameter ratio screw, plasticizing effect is better, pressure is more stable.

3, the die is made of alloy material, reasonable structure, wear resistance, uniform heat, easy adjustment.

4, melt metering pump quantitative pressure output, and equipment pressure and speed closed-loop automatic control.

5, the distributor precision adjustable control, level ratio accurate.

6, three roller independent adjustment is consistent, synchronous adjustment operation is convenient.

7, equipped with double station electric winding, easy to change, winding flat, reduce waste.

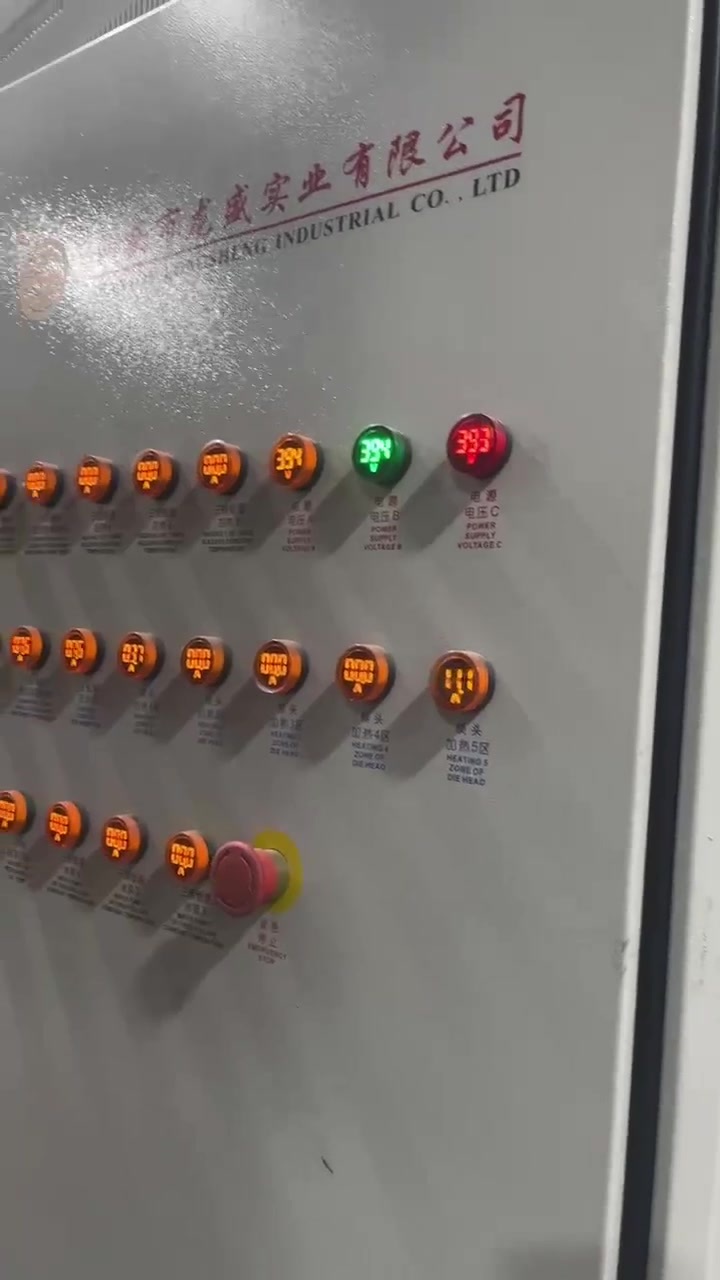

8, using PLC control, to achieve parameter setting, data calculation and feedback, alarm and other functions of automatic control.

The China Sheet Extruder Machine is engineered for superior performance in producing plastic sheets, offering energy-saving operation, stable output, and precise thickness control. Designed with advanced technology, this extruder features an amorphous alloy steel screw and high-performance barrel, ensuring efficient melting, extrusion, and smooth sheet formation. Its PLC control system enables automated temperature, speed, and thickness adjustments, minimizing errors and optimizing productivity.

Key benefits include low maintenance costs, noise reduction, and long service life, thanks to its robust, wear-resistant components. The machine supports a wide range of materials, including PET, PP, PVC, and PE, making it versatile for packaging, construction, and industrial applications. With a modular design, it adapts to various production needs, from small-scale workshops to large-scale factories.

Manufactured in China to ISO and CE standards, this extruder combines cost-efficiency with reliability, backed by rigorous quality control. Its user-friendly interface and quick-change molds streamline operation, while optional edge trimming and online cutting systems enhance flexibility. Ideal for eco-conscious producers, it delivers consistent sheet quality with minimal material waste.

Extruder screw | φ120,φ105,φ90 |

Maximum extrusion output | φ120≤360kg/h,φ105≤240kg/h,φ90≤160kg/h ,TOTAL≤760kg/h |

Handle materials | PS,PP and so on. |

Product Specifications | Width ≤850mm, thickness 0.4-2mm |

The thickness of the product | ±0.015mm |

Size | About L=12M,W=2.5M,H=3M |

| Roller specification | Φ520×1000mm=1 PCS,Φ700×1000mm=2 PCS, |

Power | 380V/50HZ+E(Three-phase four-wire system) |

| Air Source | 0.8Mpa |

Cooling water | Soft water in medium at 5 to 25 degrees Celsius |

Total power | About 500Kw/h |

NO. | ITEM |

1 | China Jingcheng Times GD-DSP-150 plate screen changer |

2 | China Jingcheng Times GD-DSP-120 plate screen changer |

3 | China Jingcheng Times E70 integrated metering pump |

4 | China Jingcheng Times E56 integrated metering pump |

5 | China Jingcheng Times E45 integrated metering pump |

6 | China Jingcheng Times Three-layer extrusion distributor |

7 | Three sets of static mixers (built-in in the flow channel) |

8 | China Jingcheng Times 1000 hanger type mold |

9 | Inclined horizontal three-roll calendering machine |

MADE IN CHINA

Related Video

三辊杆

三辊杆

三辊杆

三辊杆

Machine Details

Contact Us

China Shantou Longsheng Industry Co., Ltd.

Address:No.44 Xigang Road, Shantou, Guangdong, China

Mob: +86-13302710116

Shiela:+86-15362312727

E-mail: longshengmachine@gmail.com

TikTok